Bridge Abutments & Why They Require Scour Protection

Hydraulic scour destabilizing bridge abutments is a leading cause of bridge failure in the U.S. and around the world. Combating this common form of erosion is both imperative and challenging, given the naturally dynamic bankside and shoreline environments and the frequently unconsolidated or otherwise unstable sediments where bridges are needed.

Fortunately, HYDROTEX fabric-formed concrete offers versatile, customizable, and long-lasting bridge-scour protection. Read on to learn more about the issue, and how our products help tackle it!

Hydraulic Scour Around Bridge Abutments

Bridge scour refers to the removal by hydraulic forces of sediment around abutments and piers. It results from the interaction of flowing water and these man-made obstructions, though it can be instigated or enhanced by natural processes such as riverbank undercutting by meandering rivers, erosion of tributary channels, and coastal erosion from breaking waves.

Flowing water, whether a river or tidal current, forms eddies and vortices downstream of a bridge abutment as well as a bridge pier. This can cause localized scour directly around these structures. Water passing through a constriction, as formed by the chokepoint of bridge abutments along a riverway, speeds up, gaining erosive power and generating vortices to produce contraction scour.

These and other forms of scour can create scour holes on the downstream side of abutments as well as gnaw away at riverbanks or coastal bluffs. Such hydraulic scour and erosion destabilizes bed and embankment surfaces, causing abutments to lower, lean, or even collapse. Given the critical support bridge abutments provide at either end of bridge spans, it doesn’t take much deep thought to recognize the perilous impact hydraulic scour can have: resulting, at best, in costly repairs, and at worst in all-out bridge collapse and loss of life.

Combatting Bridge Scour With HYDROTEX Fabric-Formed Concrete

Armoring is the leading countermeasure when it comes to bridge-scour mitigation. From matrix and grouted riprap to gabion baskets and retaining walls, bridge-abutment armoring can take a wide variety of forms.

But such mass-manufactured installations often leave much to be desired, if they can even be effectively installed in the first place. HYDROTEX fabric-formed concrete provides the better solution in many contexts.

Because it can be produced exactly to specifications (width, length and thickness), and laid out unfilled to precisely conform to abutment structures before being pumped with fine aggregate concrete in situ, our fabriforms provide a truly custom solution with exceptional, long-lasting scour protection.

Compared to mass-produced and pre-cast alternatives, our HYDROTEX fabriforms offer low-cost transport and can be efficiently installed without heavy machinery or a large, specialized work crew. The ease with which HYDROTEX can be installed extends to underwater and low-head clearance applications. Many times, no excavation is required to put in our fabriforms, and they can be installed in low-clearance and other logistically tricky sites. And they can be effectively used for any number of kinds of bridges—highway bridges, railroad bridges, etc.—and in a multitude of settings and scales.

HYDROTEX Products Ideal for Bridge Scour Protection

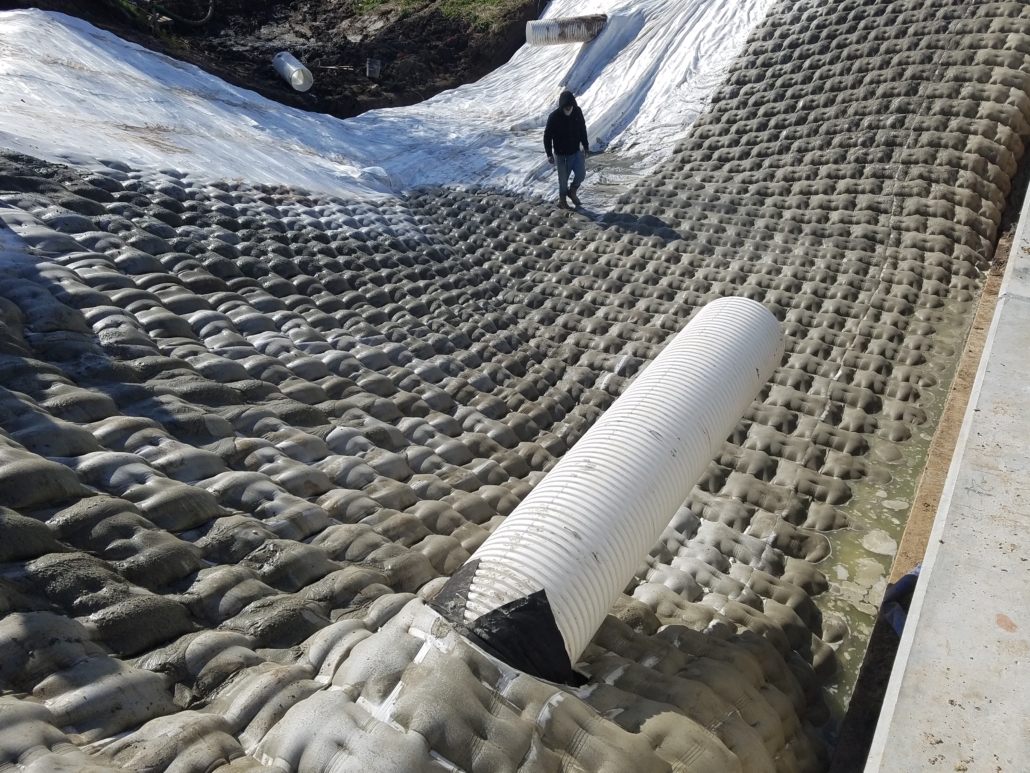

The number-one go-to HYDROTEX product for bridge-scour prevention is our Articulating Block Fabric Form. These cast-in-place concrete mattresses come reinforced with internal revetment cables (either steel or polyester cables) to provide rock-solid but flexible scour protection that stands up with minimal maintenance for the long haul. Pumped with fine aggregate concrete in situ, our articulated block mattresses provide a superior armoring solution for bridge abutments regardless of design style or location.

Along with our top-quality articulated block mats, you might also choose our HYDROTEX Grout Bags for bridge-scour repair. These cast-in-place concrete bags can fill up scour holes and prop abutments back up to level. These fabriform concrete bags can be produced to exact-specification height and width to deliver custom bridge-scour protection solutions for any kind of bridge abutment.

And in many cases, both articulating block and grout bags can be used in coordination with each other. Between our articulated block mattresses and concrete bags, you’ll be able to address any bridge-scour issue head-on!

The Synthetex Solution for Bridge Abutment Scour

The Synthetex approach gives you more than just a (fabulous and first-rate) solution for bridge scour protection and bridge scour repair. We’re with you every step of the way, from helping plan out the exact custom design and specifications to meet your needs to providing contractor bidding as well as on-site technical support and planning consultation for contractors. We’re not just a materials supplier here at Synthetex: We’re your partner on the project!

Turn to Synthetex HYDROTEX Fabric-Formed Concrete to Combat Bridge Abutment Scour

Whether you’re addressing bridge scour already underway or trying to prevent it in the first place, look no further than HYDROTEX fabric-formed concrete! Our 100% customizable articulated concrete mattresses and erosion-control bags provide easy-to-install, highly cost-effective, and top-performing solutions.

Get in touch with Synthetex today to find out more about how our HYDROTEX fabric formworks can address bridge abutment scour on your project. For a free consultation and project estimates, call us at 1-800-253-0561 or 770-399-5051 or touch base via our online contact form.