The Advantages for Utilizing Cooling Ponds at Industrial Facilities

Cooling ponds are an essential element of many industrial sites. These bodies of water require linings and erosion protection, which is exactly where Synthetex—and, of course, our HYDROTEX fabric-formed concrete products—come marvelously into play.

If you’re looking for a custom solution for lining and bolstering your cooling pond—and one that won’t break the bank when it comes to freight, lay-down space, installation, and maintenance—we’ve got just what the doctor ordered here amid the Synthetex HYDROTEX inventory. Read on to find out more!

The Importance—and Advantage—of Cooling Ponds at Industrial Sites

Water heated by a wide variety of industrial activities can be cooled down and recirculated efficiently via cooling ponds. These are fixtures of a variety of settings, including coal-fired power plants, nuclear power plants, petroleum refineries, paper mills, and steel mills.

Cooling ponds offer the advantage of available water resource, multifunction as a settling solution, and the benefit of rainwater boosting the intended purpose, among others.

HYDROTEX Technology at Work in Industrial Cooling Ponds

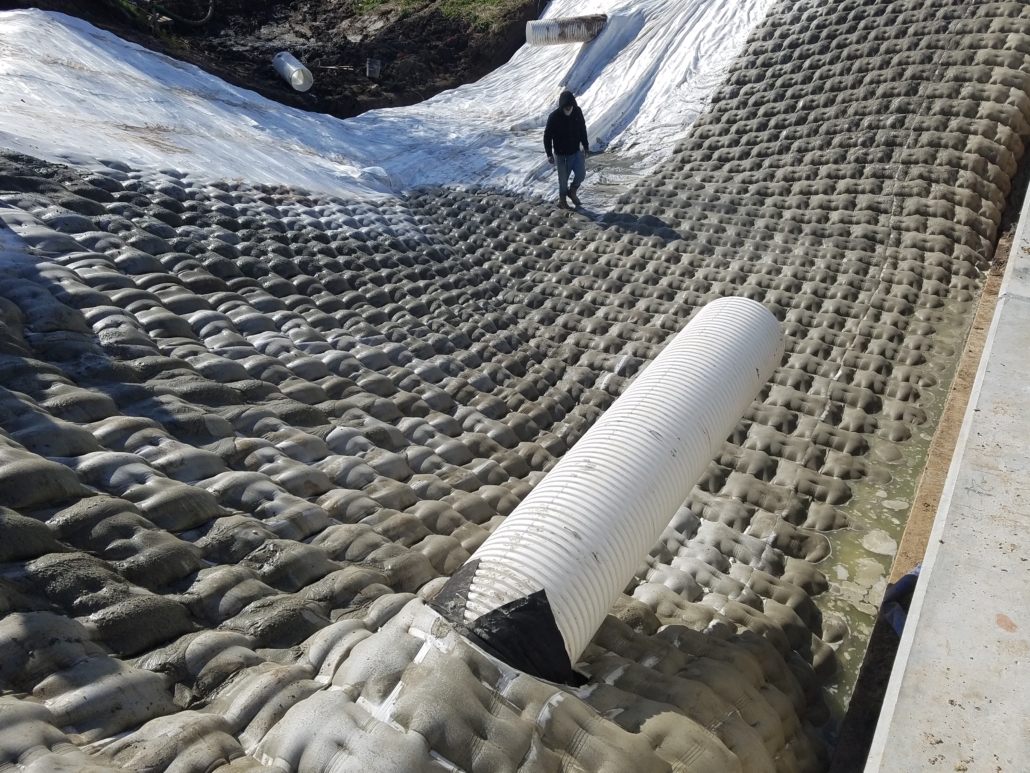

For lining cooling ponds and protecting them from erosion—not to mention cutting down on vegetative buildup that can otherwise degrade the function of these water bodies in the first place—look no further than HYDROTEX fabric-formed concrete from Synthetex. Our top-of-the-line fabriforms offer completely customizable, thoroughly adaptable cast-in-place solutions. Compared with pre-cast alternatives, HYDROTEX fabric formworks translate to exceptional cost savings when it comes to freight, required storage space, site safety, small skidsteers, little labor, no dewatering, and installation speed.

A number of specific HYDROTEX products can be tailor-made for industrial cooling ponds. Those include HYDROTEX Uniform Section Concrete Linings, an incredibly versatile option. Also prime for this application is HYDROTEX Filter Point technology, ideal for reducing flow velocities and wave run-up while relieving hydrostatic uplift pressures, as well as HYDROTEX Articulating Concrete Linings, similar to the Filter Point product for hydrostatic uplift relief, but with pre-installed revetment cables and a higher Manning’s n, preferred when even greater reduction of uplift pressure, flow velocity, and wave run-up is desired.

And because cooling ponds typically cover many acres, wave action impacts along the shoreline resulting from wind during storm events can be evaluated by our civil engineers.

The good news is you don’t have to wrestle all on your lonesome with selecting the ideal HYDROTEX fabric-formed concrete product for your needs when it comes to your cooling pond(s). Our team of engineers are here to help advise you on that front. The incredible versatility of our fabriform technology, the fact that these fabriforms can be customized to just about any site, setting, and function—well, needless to say it all adds up to the prodigious appeal of Synthetex solutions on this front.

Synthetex High Quality: Top-Quality Product & Attentive Expertise

Custom-sized to the job, installed in situ before being pumped with fine aggregate concrete, HYDROTEX fabric-formed concrete delivers a highly adaptable, highly durable, and supremely low-maintenance long-term lining and anti-erosion solution for industrial cooling ponds.

These fabriform products are fabricated by Synthetex to the dimensions of your project. Our HYDROTEX fabric-formed concrete works as well for underwater installations as in dryland applications. Incredibly easy to transport, put in place without the need for major manpower or heavy equipment, these fabric formworks are highly desirable compared to pre-cast concrete options. Maintenance—and therefore long-term costs—are minimal.

From planning the perfect HYDROTEX product for your needs to providing technical consultation throughout the process—including on-site assistance during installation—the Synthetex engineering and field teams area here for you every step of the way.

Look to Synthetex & HYDROTEX Fabric-Formed Concrete for Cooling Ponds

Don’t hesitate to reach out to us for more information on how HYDROTEX products can bolster the long-term integrity and performance of your industrial cooling pond. There’s no job too large or too small for the Synthetex treatment, and our deep experience and high-caliber materials mean we’ve surely got exactly what you need for your project, wherever and whatever it is. Here at Synthetex, we’re proud to offer free consultations for delving into details and hashing out design details. So what exactly are you waiting for? Drop us a line over the Synthetex website, by calling 1-800-253-0561 or 770-399-5051, or by filling out our contact form to get started.

We very much look forward to discussing how HYDROTEX Uniform Section, HYDROTEX Filter Point, Articulating Block and other Synthetex fabric-formed concrete products can integrate into your industrial site!